BY TITANIUM

Given the devastating consequences fire can inflict on human life, wildlife, and property, fire resistance will always be a priority when it comes to the design and construction of homes – including the roof. Concern about the fire-resistance of structures is especially high in critical environments like Wildland Urban Interface (WUI) zones.

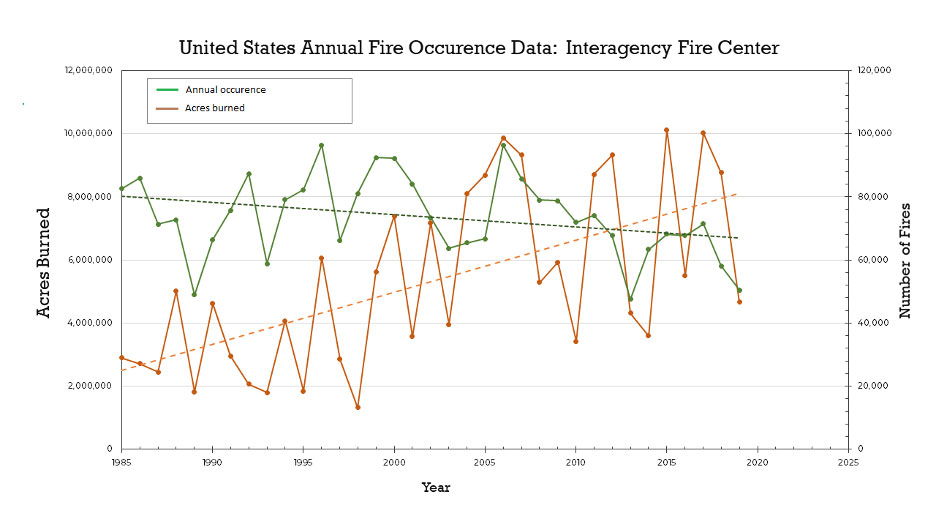

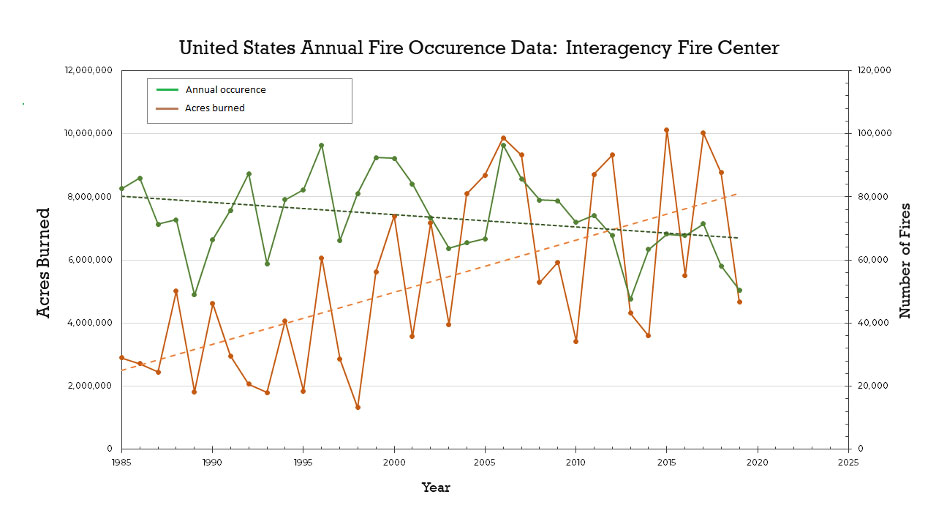

Although fires are not necessarily more common in the U.S., they are becoming more common closer to WUI zones according to Dr. Ian Giammanco, managing director for standards and data analytics at the Insurance Institute for Business and Home Safety IBHS and a research meteorologist. “Human activities, whether electrical activities, homes being built closer together or construction moving closer to wildland areas means fires are increasingly a concern at the WUI,” says Dr. Giammaco.

While electrical concerns like energy-generating roof assemblies did not contribute to historic fires of centuries past, Dr. Giammaco notes that the denser construction practices seen near WUI areas today are similar to the practices in the 18th, and 19th centuries that led to homes being “sandwiched” together and destroyed by catastrophic fires.

Along with sustained periods of drought in some parts of the country, increased construction in WUI zones helps explain why more efforts are being undertaken to reduce wildfire risk. As an example, Wildfire Prepared is a voluntary, research-based mitigation and assessment program developed by IBHS that is designed to meaningfully reduce wildfire risk. These efforts include specifications for every part of the house and surrounding property – from fences to walls to roof assemblies. Given the volume and size of airborne burning brands present during a wildfire, advancements in building science are helping provide fire-resistant roofs that are capable of helping to curb the spread of wildfires from home-to-home.

Reprinted, with permission, from ASTM E108-20a, Standard Test Methods for Fire Tests of Roof Coverings, copyright ASTM International. A copy of the complete standard may be obtained from www.astm.org.

Fire-Resistant Classifications for Roofs

Before discussing innovations to support safety at a home’s roof, it’s helpful to consider how roofs are classified and tested. Residential roofs are evaluated as assemblies (including the roof covering, underlayment, and roof sheathing) and are tested and listed according to three classifications:

Class A – effective against severe fire exposure

Class B – effective against moderate fire exposure

Class C – effective against light fire exposure

Two code required tests – ASTM E108 and UL 790 – are used to classify residential roof assemblies. These tests are intended to evaluate the ability of a roof assembly to resist the penetration or spread of flames to the interior of a structure, allowing more time for a home’s occupants to evacuate. The testing process is very similar for all roof assemblies including those incorporating asphalt shingle and metal roof coverings. Solar (PV) assemblies are tested with a burning brand on top of the PV panel and between the PV panel and the roof covering.

The Testing Process

The burning brand test evaluates the ability of a roof assembly to resist ignition of the underside of the roof sheathing as the assembly is exposed to a 12 mph wind velocity. When shingles are tested, the most acute point of vulnerability is typically the area at the intersection of the horizontal and verticaljoints in the deck. With concrete or clay tile, the tile can break anywhere allowing for glowing pieces of the brand to fall into those cracks. The ability of the underlayment to resist conducted heat is critical when testing metal roofs as metal rapidly conducts heat into the underlying materials.

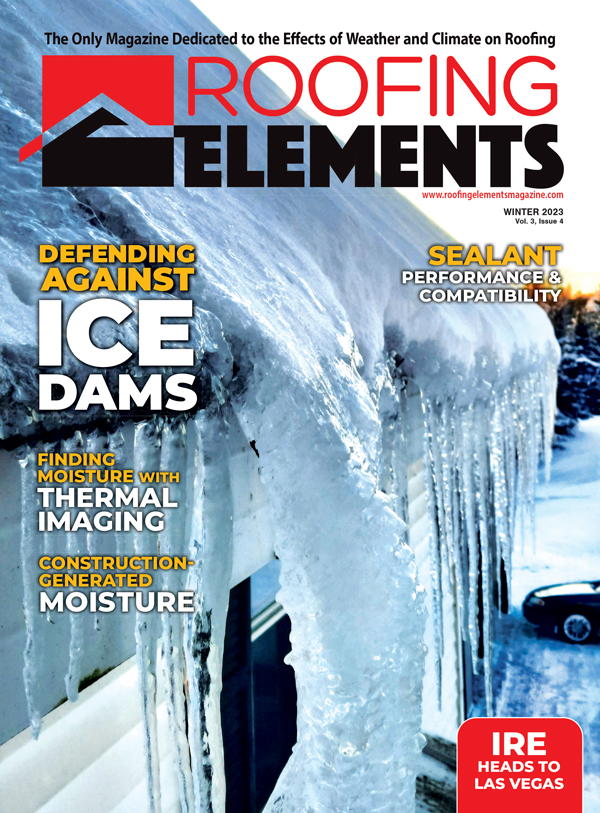

The burning brand test for the various classes includes a different number and size of brands for each class:

Class A

The brand is 12 inches x 12 inches by 2.25 inches, and is constructed of hardwood pieces with air spaces in between. The brand is ignited on all 6 sides for a specified period of time, and placed in the most vulnerable area of the deck (top of the brand 3 inches above the horizontal joint in the deck).

Class B

The Class B burning brand test incorporates two brands that measure 6 inches x 6 inches x 2.25 inches, also constructed of hardwood pieces with air spaces in between. One brand is ignited on all 6 sides, then placed on the roof deck with the top edge 1.5 inches above the horizontal deck joint, and at least 6 inches from one edge of the deck. Once the first brand has burned completely, the second brand is placed on the deck at least 6 inches from the opposite edge of the deck.

Class C

Class C brands are much smaller at 1.5 inches x 1.5 inches x .75 inches. The Class C test incorporates placement of 20 of these brands across the deck. The Class C test is not a stringent test at all. Solar panels in and of themselves tend to be tested to C, which is easier for the panels to pass.

The total time of the burning brand test is 1.5 hours, or until all burning activity ceases – whichever is shorter. Many asphalt shingle decks pass at between 45-50 minutes based on performance observed. Generally, if there is no sign of fire activity on the deck, if the temperature is in the 250°F to 300°F range and if there aren’t any glowing brands coming off the deck, an assembly is considered to pass the test – even before the 1.5-hour test is up. By the same means, if the deck is still blowing red hot and 1.5 hours passes, an assembly is considered to have passed the test.

Finally, the arrangement/coursing of the roof covering is such that the fewest number of layers in the system are covering the horizontal joint in the sheathing.

Considering Energy Generating Systems

Energy-generating systems present special challenges for fire resistance. The PV cell encapsulant in solar panels is highly flammable. When the encapsulant catches fire, the other components of the roof assembly work to protect the deck from the massive amount of heat generated by the fire that is generated. Class A is not required for the PV modules themselves – Class C is the minimum requirement and typically what’s achieved in such assemblies.

Designing Class A Assemblies – Underlayment Considerations

Underlayment plays an essential role in supporting the performance of roof assemblies – including fire resistance. Acknowledging trends and a market need for more Class A assemblies, engineers and scientists conducted extensive research and testing to formulate and produce a fire-resistant synthetic underlayment that can stand up to Class A testing requirements. The initiative led to Titanium® FR—a cost effective approach for passing the rigorous testing required for Class A materials.

While safety is always the highest priority, other factors also inform an underlayment selection decision. Walkability, tear-resistance, and ease of install are all criteria to evaluate, along with a material’s ability to withstand UV exposure. Selecting an underlayment that can be installed in a single layer minimizes labor and supports efficiency on the jobsite. A real differentiation in Titanium® FR is a surface that supports walkability and slip-resistance. The product was also designed to be tear-resistant, easy to handle and handle up to 180 days of UV exposure. Building on years of research, the formulation includes a proprietary blend of fire-resistant technologies including retardant blend and facer. It was first introduced at the International Roofing Expo in 2023.

Looking Forward – Finding a Common Language

In speaking with firefighting groups, code officials and stakeholders across many jurisdictions, it is apparent that the industry suffers from inconsistency in the language used to address fire resistance. There is a lot of debate at the international code level regarding the semantics of fire resistance, classifications and listings and a task group is working to make language more consistent.

The severity, size of fires and subsequent losses suggest that the risk is going up. All parts of a home should be considered as wildfire readiness demands a “system approach” according to Dr. Giammanco . When it comes to the roof, selecting roof assembly components that can stand up to the harshest conditions as reflected by Class A roofing assemblies measured per ASTM E108 or UL 790 can support specifiers in recommending products for traditional steep slope and energy-generating roof assemblies. l

www.titanium.com