WHAT FACTORS TO CONSIDER AND WHY

Year-after-year, rooftop avalanches cause hundreds of millions of dollars in property damage, personal injury, and even death. Snowpack can suddenly release and dump tons of snow below the eaves in a matter of seconds—endangering building elements, adjacent roofs, landscaping, vehicles, property, and, even worse, pedestrians. Inadequate snow guard systems (or none at all) create a life-safety issue and potential liability for building owners, designers, and contractors.

The best way to mitigate this avalanche danger on a metal roof and reduce liability caused by sliding snow and ice is by installing a scientifically tested and engineered snow retention system specific to the snow loads expected on the particular metal roof profile.

A snow guard is a device or system that mechanically provides a frictional interface between the roof and the snow, so that snow evacuates the roof in a predictable and controlled fashion, rather than by a sudden and dangerous rooftop avalanche.

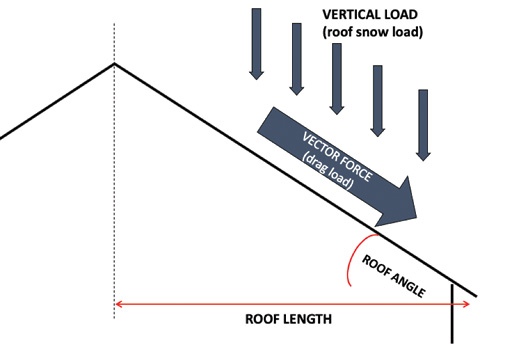

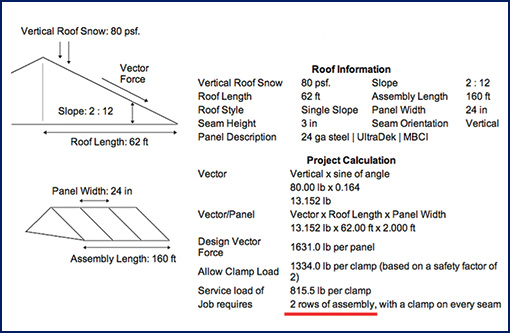

This calculation should be done for any snow retention system. System

testing must prove strength of system exceeds this calculated force.

Vector (PSF) = Vertical (PSF) x Sine of Roof Angle

Vector (Pounds per Panel) = Vector (PSF) x Roof Length (Ft) x Panel Width (Ft)

Understanding the Math & Science

The forces of snow on your rooftop can be mathematically calculated, and should be for any snow guard system. The service loads applied to a snow guard system are a relatively simple calculation, varying with site specifics, all of which should be known to the design team: 1. the design roof snow load, 2. roof slope, and 3. roof length (eave-to-ridge). These three factors determine the vector force that a system must resist for any roof surface and should be included in plans and specifications requiring an engineered system.

Snow Retention System Design Considerations

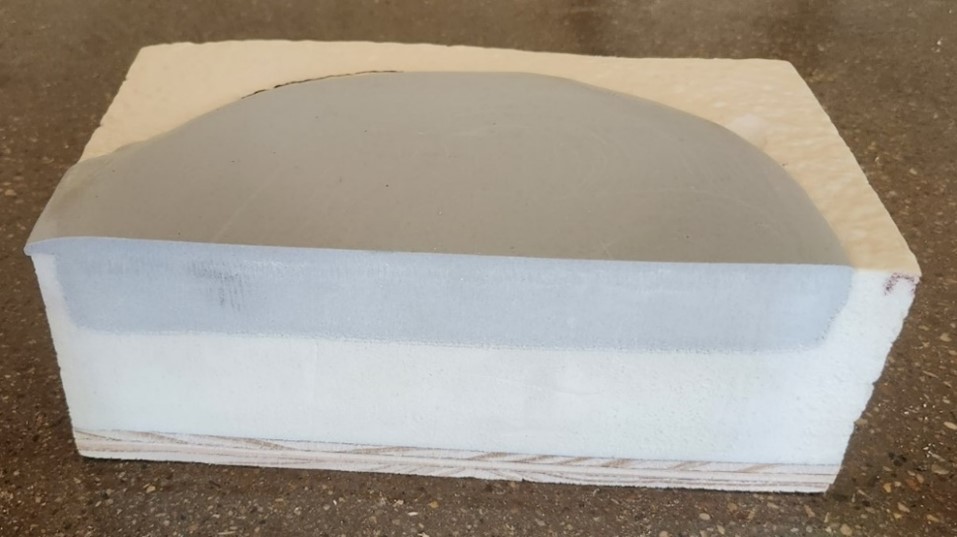

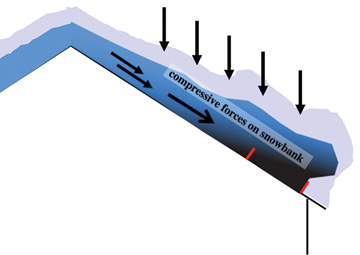

Snow Retention Population and Placement: Snowbanks typically accumulate and densify in a cross-sectional wedge pattern. All snow guards rely on the snow’s own compressive strength to restrain its movement. Gravitational forces compress the snowbank mostly at its interface with the roof surface, especially toward its lower (eave) end—so this is where compressive strength is greatest. The interface of snow retention devices at this location has proven to be strongly preferred worldwide and considered to be most effective.

Snow guards rely on compressive strength of the snowbank (greatest at snow-roof interface and lower end of the roof).

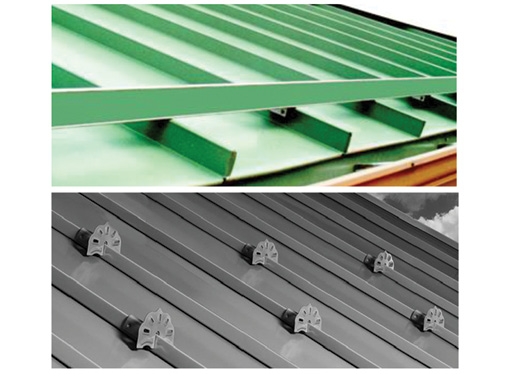

System Design: Two snow guard system designs are quite common. One utilizes continuous horizontal components, assembled laterally across the roof in the style of a “fence.” Such assemblies are usually installed at or near the eaves. Depending on specific job conditions and load-to-failure characteristics of the devices, they may also be repeated in parallel rows up the slope of the roof, but with greater concentration near the eave area.

The other design consists of small, discontinuous individual units used as “cleats,” generally spot-located at or near the eave or repeated in a pattern progressing up the slope of the roof, again with a greater concentration near the eaves. This style also relies upon the shear strength within a snowbank to “bridge” between the individual units.

Both styles of snow guards (fence and cleat) have demonstrated satisfactory performance when tested, engineered, and installed properly and adequately.

Top: A “fence” (continuous) type snow guard

Bottom: A “cleat” (discontinuous) type snow guard

Snow Retention mounting Techniques

There are three techniques for mounting snow retention systems to a metal roof. Two use mechanically attached snow guards. The distinction between the two involves clamping, which grips the standing seam in some fashion without actually puncturing the panel material (non-penetrating) versus fastening screws through the roof material (penetrating) into the structure. The third uses a chemically attached “stick-on” adhesion method, which involves gluing individual snow guards to a roof surface.

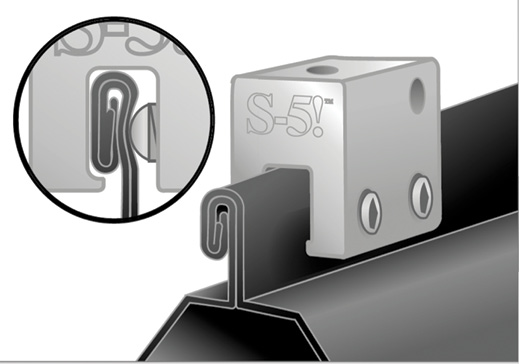

Mechanical clamp attachment with round-point setscrews is advocated by MCA, MBMA, and USDOD.

1. Clamping a Snow Guard to a Standing Seam Type Roof: This method uses a seam-clamping attachment, and is a secure option for a standing seam metal roof profile. Clamps attach directly to the roof seam using setscrews that do not penetrate the roof (mechanically-attached).

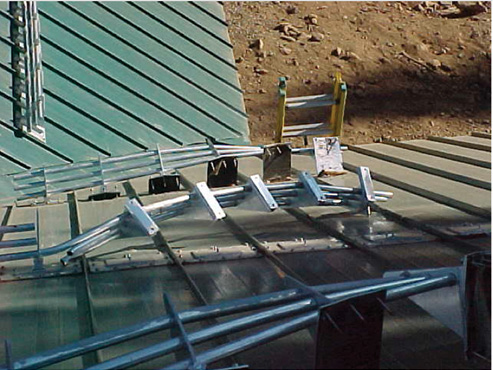

2. Attaching to the Building Structure Itself: The second method for mounting snow retention is a system that attaches snow guards through the roof and into the building structure (also a mechanical attachment). Attaching to the building structure provides a secure and reliable method if properly tested, designed, installed, and waterproofed (see below).

Mechanical bracket attachment (for face-fastened roofs only) can also work successfully when tested and engineered correctly. This one wasn’t.

3. Using a Stick-On Guard: The third type of snow retention is a stick-on (adhered) part (a chemical attachment). Some variations employ a factory-applied adhesive, while others use a field-applied one. At a glance, stick-on snow guard systems appear to be a very convenient and low-cost option, but they are only lower in cost when you consider part costs versus total project costs (including labor and quantities required to do the job).

Moreover, the replacement costs over the life of the roof are extensive when, not “if,” the adhesive diminishes in holding strength. Adhesives all diminish in holding strength, beginning with the first day of exposure. Replacement time is often relatively soon after installation, depending on orientation to the sun and other environmental factors.

How to Choose the Best Snow Retention System for Your Project

Numerous snow guard vendors have appeared in the market, each claiming to be the best, ultimate, first, or strongest. There are no industry standards or mandates for design, manufacturing, use, or testing of snow guards—no “snow guard police”—so this market space is completely unregulated. It is a “buyer-beware” scenario as to the appropriateness and proof of testing and engineering performed by the vendor.

Vet and Specify: Manufacturer transparency is requisite to adequately vet a snow guard system. A vendor who lauds the capabilities of their system but fails to provide proof of those claims may be blowing smoke. The designer should scrutinize manufacturer qualifications/certifications to ensure a safe, engineered application and long-term service. This transparency should extend from raw material sourcing through manufacture and product handoff. Scrutiny of the vendor’s evidence provides credibility and assurance to the buyer. A qualified manufacturer should gladly provide proof of their claims.

Proof of Testing: Anchorage of clamps to the roof specimen should be repetitiously tested on the specific material, gauge, and roof profile. A minimum of three test repetitions should be conducted (fewer will not offer a scientifically acceptable statistical average). Testing of all system components should be conducted by a third-party ISO 17025-accredited lab and be specific to the exact roof and brand used on the project.

It is also not scientifically acceptable to apply a test result from one set of test specimens to another similar-style roof product. Request test reports from the vendor, proving anchorage values of the appropriate testing used in engineering calculations. Ideally, panel-specific test results should be available to you and published on the vendor’s website.

Proof of Engineering: Project-specific engineering should be provided by the vendor and incorporate the tested strength of the system with an appropriate factor of safety applied. Insist that calculations are provided prior to product selection. Ideally, the vendor should offer a web-based calculator with real-time output showing calculations and allowable loads specific to your project, including product names of snow guard systems and specific brands of roof manufacture.

At a minimum, require these calculations with submittals. Better yet, have the vendor provide them stamped by a registered Professional Engineer.

Proof of Certified Manufacturing: How can you know the product tested is really the product purchased? Systems may look the same, but alloys, tensile strength, yield, and other mechanical properties should be verified through certified manufacturing with third-party audits in an ISO 9001-15-compliant facility, not because one looks the same as the other. Ask to see the current ISO Certificate. It should be displayed on the vendor’s website.

Warranties: Does the manufacturer offer meaningful product defect and performance warranties? Obtain copies prior to purchase—and read the fine print! They should also be displayed on the vendor’s website. Will the vendor be in business for the long term to honor them if needed? Has the vendor substantiated its track record? How long the company has been in business is irrelevant. The question is, “How long and on how many projects has the system you are buying been in use?”

An example of a typical output sheet from valid calculation.

A Proof of Certified Manufacturing should be displayed on a vendor’s website.

Why Use Snow Retention?

Metal roofs are known for their durability, sustainability, and versatility, but are slippery and can pose potential of rooftop avalanches in the discharge areas below the eaves, causing property damage, personal injury, and even death.

A tested and engineered snow retention system increases the friction between the roof and the snow, so the buildup of snow and ice on a roof evacuates in a predictable and controlled fashion rather than by a sudden release of sliding snow. At S-5!, we have tested and retested our clamps with almost every metal roof profile. Results are available on our website under the “Load Test Results” tab.

A smart and rather low-cost investment in a snow retention system specific to your metal roof profile not only protects the roof and roof elements, but protects the rest of the building and its occupants. It reduces short-term and long-term maintenance costs and most of all, reduces the potential liability for building owners, designers, and contractors.

For information, videos, and webinars on this topic and more, visit www.s-5.com or www.metalconstruction.org.

Rob Haddock, the inventor of metal roof attachment solutions, is a former contractor, award-winning roof-forensics expert, author, lecturer, and building envelope scientist. Haddock has worked in various aspects of metal roofing for nearly five decades.