By The Metal Roof Experts™, S-5!

Metal roofing is known for its durability, long-lasting performance, and reliability. The exceptional performance of metal roofing in high-wind conditions is due in part to its attachment methods and interlocking installation where roof panels are overlapped and attached to the structure of the building, reducing the ability of wind to disrupt the panels.

Standing seam metal roofing has an advantage over other roof types, such as membrane and hot-applied asphaltic roofs, because it serves as a “structural” covering, meaning it can be engineered to withstand almost any force imposed by wind. When so designed, some structural standing seam profiles can withstand extremely high forces, often making metal the roof of choice in high-wind regions.

Design Wind Speeds & Wind Forces

Wind speeds vary throughout the United States with high wind-prone areas found in coastal communities and in some mountainous regions, and lower wind-prone areas found in much of the interior states. The design wind speed is primarily determined by the area’s highest recorded 3-second wind gust (measured 33′ above ground), which in turn is used to calculate the maximum overturning forces on a building and maximum uplift forces on a roof.

Wind speed (mph) has to be translated into units of force (psf) for design purposes (in accordance with ASCE-7—Minimum Design Loads and Associated Criteria for Buildings and Other Structures). The resulting forces can be different in various roof zones. A building’s size and geometry impact those forces and zones. For example, a 60′-tall building experiences stronger wind forces than a 30′-tall building, even if both are in the same area with the same design wind speed. The overall terrain and the building’s immediate surroundings also impact wind forces. Valleys, hills, slopes, and cliffsides, as well as obstacles in the wind’s path, such as nearby buildings and wooded areas, can reduce—or in some cases—increase wind speed/force. Open terrain or open water can also set the stage for increases.

Wind Uplift: a Design Engineering Consideration for Any Roof

Proper roof design depends on the region’s design wind speeds and how the aforementioned factors alter the wind forces acting upon it. No matter where a building is located or what it is constructed from, there are minimum standards of forces it should withstand, including wind uplift forces on its roof. So, the roof must be strong enough to withstand the maximum uplift design forces determined for the building. As the minimum uplift forces increase in areas with higher winds, such as hurricane-prone areas, roofs must be more durable. Metal roofing lends itself to high wind-prone areas since it can easily be engineered to withstand nearly any uplift force.

Impact of Metal Roof Design on Wind Resistance

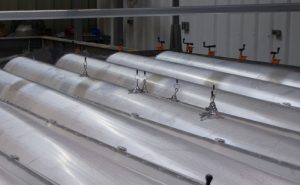

Metal roof installation methods are relatively similar everywhere, but it is the building and the roof system design that affects resistance to wind forces. Critical design factors impacting the roof’s strength include roof panel design and thickness, the clips attaching the roof to the underlying structure, and the underlying structure itself (rafters and purlins). There is a myriad of choices for roof panels, all with various strength characteristics.

Some standing seam roofs and clips are designed specifically for tremendous uplift performance. Features can be manufactured into the roof, such as rib shape and increased metal thickness, that control the roof stiffness and strength. Additionally, the appropriate clip must be used to meet the wind uplift requirements for each building—not all clips are the same. Various materials, material gauge, length, and points of attachment all affect the performance of the clip. For example, one might use a 26-gauge clip to obtain a specific wind rating, while one might use a 22-gauge clip to increase the performance—should the failure mode be the strength of the clip.

Using more material to increase wind uplift performance can be done either by increasing material thickness or just using more material in general—either in the clip (more folds, longer length), the seam (more folds), and/or decreased clip spacing (more clips). Installing additional clips (attachment points between the roof and structure) increases the roof’s wind resistance. The number of purlins installed on a building impacts the overall strength of the roof and controls the allowable attachment points.

Finally, new or existing uplift performance can be significantly increased with the use of externally applied clamp products for a comparatively low cost. Placed over the roof’s seams at designated intervals, these external clamps can increase the roof’s wind-resistance capacity, preventing multiple modes of failure, including seam separation and clip disengagement when used at roof clip locations.

Testing Standards for Wind Resistance

As discussed, metal roofing is designed for buildings throughout the country and around the world, with varying resistance to wind forces. So, materials, products, and designs are tested for all wind pressures in those markets to demonstrate their strength. Thus, various resistances to wind force can be attained through testing specific roof system assemblies.

UL 580: Tests for Uplift Resistance of Roof Assemblies is one of these test standards. The uplift resistance of a roof assembly is listed as Class 15, 30, 60, or 90. The spectrum of 15 to 90 is comparative ratings, which are not related to specific wind speeds. For example, Class 90 involves 56.5 psf vacuum pressure and 48.5 psf upward pressure from below on a 10′ x 10′ specimen anchored at its perimeter.

Another test standard, FM-4471: Approval Standard for Class 1 Panel Roofs/Roof Assemblies lists roofs to Class 1 to 60, 90, 120, 150, and 180. The nomenclatures 60 to 180, in the FM standard, relate to static pressure—also not wind speed but a larger specimen.

The most notable test standard is ASTM E1592: Standard Test Method for Structural Performance of Sheet Metal Roof and Siding Systems by Uniform Static Air Pressure Difference. This is somewhat different from other test standards whereby sample roof assemblies are subject to increasing loads until failure. The maximum load obtained is published as an ultimate load, and a design load is determined from the appropriate safety factor, which is then used to select a system for wind pressures.

Main TakeAway

With appropriate design and testing, metal roofing affords greater durability than other roof types and is particularly critical for use in high-wind areas. According to Monroe County, Florida’s staff summary, post-Hurricane Irma inspections found that “metal roofs fared far better than those roofs covered by asphalt shingles” and in recent years, county officials even proposed an ordinance to require all new or replacement roofs to be metal. That’s a true testament to the sustainability and durability of metal roofing, particularly in high wind-prone areas.

ASPHALT SHINGLES

BY DAVID ELLIS AND HELENE HARDY PIERCE, GAF

We discussed the concerns regarding wind uplift and asphalt shingles with David Ellis, Vice President of Residential Marketing, and Helene Hardy Pierce, Vice President of Technical Services, Codes, & Industry Relations, both with GAF. They share their knowledge here:

Roofing Elements: Is wind uplift always a concern for asphalt shingles? Or is it a regional issue (only in hurricane-prone areas, etc.)?

David Ellis: Winds affect nearly everyone, nearly everywhere. In fact, damage from severe thunderstorm winds accounts for half of all severe weather reports in the lower 48 states.

Roofing Elements: What unique problems are asphalt shingles prone to when it comes to wind? Curling, tearing, or something else?

David Ellis: There isn’t a “unique” problem with asphalt shingles per se, but what is often misunderstood is that if all of the necessary components that provide wind resistance are not present or are not installed properly, the roof will perform poorly in a wind event.

What is often forgotten is that the installed shingle roof works as one cohesive unit. If one shingle fails to seal, then it can have a “zipper effect” on adjacent shingles where many other shingles can fail also.

Roofing Elements: How do asphalt shingle roof installation methods affect the overall wind resistance of the roofing material?

Helene Hardy Pierce: Following the manufacturer’s recommendations for proper installation is key. Not just for the shingles, but ensure all components of the roof, including the underlayments and accessories, are properly installed. Also, properly placed and “seated” fasteners are critical. If a fastener is not properly driven, it can prevent a shingle from sealing and then it will fail in a wind event, either becoming damaged or tearing apart/off.

Roofing Elements: At what wind speeds are the materials tested/rated, and how has this changed over time?

Helene Hardy Pierce: Shingles are tested and listed to either ASTM D3161 (Standard Test Method for Wind Resistance of Steep Slope Roofing Products—Fan-Induced Method) or ASTM D7158 (Standard Test Method for Wind Resistance of Asphalt Shingles—Uplift Force/Uplift Resistance Method). Our shingles carry the highest rating and are qualified for use where the basic wind speed is 150 mph. These shingles are D3161 Class F (shingles that passed testing at 110 mph) and D7158 Class H (shingles that resist uplift at wind speeds up to 150 mph).

Roofing Elements: What factors make a shingle product more resistant against high winds? Size, composition, profile/edge, or something else?

David Ellis: The quality, placement, and ability of the sealant to seal is very important (for example, shingles with a nailing area enabling a dual-phase, shingle-to-shingle seal). First, the sealant pairs with the smooth microgranule surface of the nailing area for a fast tack. Then an asphalt-to-asphalt monolithic bond cures for durability, strength, and—most importantly—exceptional wind uplift performance.

Roofing Elements: Before a shingle roof is installed, is there anything that can be done to aid in wind resistance? Specific underlayments, orientation of the roof, etc.?

Helene Hardy Pierce: Always make sure to follow the manufacturer’s recommendations. Some installation instructions may be different for high-wind areas, such as the use of six fasteners versus four fasteners. Always make sure that the starter strips are installed before starting with the roof itself and make sure that they do not overhang the eave edge too far.

Another helpful suggestion is to wait to install the roof when there will be at least some warmer days so that heat-activated sealant can seal. If you have to install a roof in the middle of colder months, you can hand-seal shingles. This is especially recommended if there is a lot of dust in the air or the roof is in a high-wind area and will be subjected to wind events before the shingles can seal.

Roofing Elements: Anything else you can share regarding asphalt shingle roofing and wind resistance?

David Ellis: GAF recently introduced the industry’s first wind warranty with no maximum wind speed limitation when installed with the required combination of accessories.

CONCRETE ROOFING TILE

By Robin Anderson, Technical Manager, Boral Roofing

There are many regions of the United States that are subject to high-wind events, and the roof structure is exposed to some of the worst wind conditions Mother Nature can throw at it. When selecting a roofing material for each particular job, choosing one that can withstand wind conditions is an important consideration. Notably, concrete roof tiles provide a high level of defense against weather-related property damage, especially when it comes to high winds.

Wind can be a complex phenomenon. It is affected by temperature and pressure differences in the Earth’s atmosphere, as well as by variations in the land’s terrain and topography. However, when wind meets a residence or building structure, the wind tends to perform in predictable ways. For example, wind meeting the side of the structure will travel up and over the roof edge with varying degrees of uplift pressure.

As an integral part of the U.S. building codes, ASCE 7-16 (Minimum Design Loads and Associated Criteria for Buildings and Other Structures) outlines some key wind uplift pressure considerations, including:

• The uplift pressures that affect a roof are highest at the corners of the roof (i.e. eave/rake corner, peak of the ridge at the rake edge).

• The edges (rake and eave) are a close second in uplift pressures.

• As wind moves across a roof’s surface, negative pressure (suction) is created and causes an uplift toward the centers of a roof plane.

Many factors influence how wind may affect a roof, such as its speed and direction when it encounters the structure. Additional factors include:

• The general design of the roof. Steep-pitched, gable roofs are more susceptible to wind uplift than the low-pitched, hipped roofs.

• Fastening methods of the tiles. The number, style, and frequency of fasteners (such as nails, screws, or foam adhesives) can significantly change the overall wind resistance of the tile’s installation.

• Local weather concerns. High Velocity Hurricane Zones (HVHZ) receive greater frequency of high winds.

• Incorrect installation. Misaligned tiles, improper fastening devices, or poorly installed flashing can reduce the roof’s performance in high-wind events.

The Tile Roofing Industry Alliance (www.tileroofing.org) also provides guidance and information on tile roofing, including both concrete and clay options and their wind resistance, stating:

“In regions prone to tornadoes, hurricanes, or extreme winds, roof tile provides one of the best defenses against wind-related property damage.

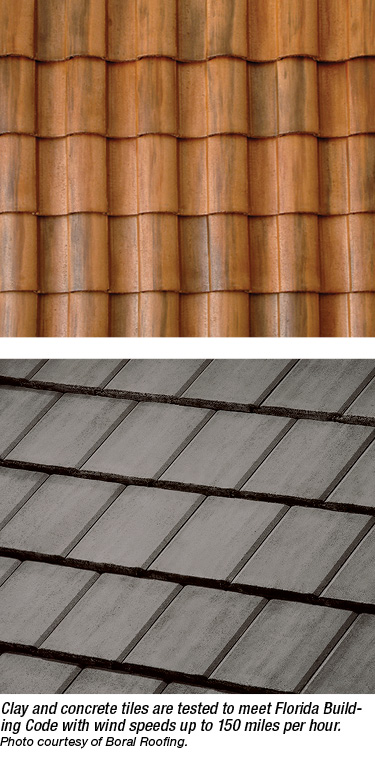

• Concrete and clay tile roofing helps in resisting hurricane-force winds.

• Natural air ventilation under the tile created by its high porosity and installation techniques used helps to relieve wind stress.

• Independent testing sponsored by the Tile Roofing Industry Alliance shows that with proper attachment, clay and concrete roof tiles can sustain winds in excess of 125 miles per hour.

• Clay and concrete tile roofing have been tested in accordance with Florida Building Code to meet Section R4402 High-Velocity Hurricane Zones—Roof Assemblies and Rooftop Structures, with wind speeds up to 150 miles per hour.”

To address wind concerns, concrete roof tiles are subjected to various wind testing that is in accordance with performance standards to determine the resistance that a given installation method meets for the design requirements in a given region. One of the world’s most stringent testing requirements is for the High Velocity Hurricane Zone of southern Florida. Some of the wind-resistance tests for tile include:

• ASTM C1568-08(2020) Standard Test Method for Wind Resistance of Concrete and Clay Roof Tiles (Mechanical Uplift Resistance Method)

• ASTM C1569-03(2016) Standard Test Method for Wind Resistance of Concrete and Clay Roof Tiles (Wind Tunnel Method)

• ASTM C1570-03(2016) Standard Test Method for Wind Resistance of Concrete and Clay Roof Tiles (Air Permeability Method)

• Testing Application Standard (TAS) 100, 101, 102, 102A, 108, 110, and 112 are all standards of procedures for testing the performance of tile roof systems

Additionally, the Southern Building Code Congress International (SBCCI) commissioned Redland Technology to investigate wind loads on roofing tile systems and to develop a code methodology. Two experiments were performed by Redland to develop their design method:

1. Wind loads were estimated from wind tunnel tests where surface pressures on medium- and high-profile roofing tiles were measured as wind was blown across a tile array.

2. Wind uplift resistance was estimated from constant displacement rate uplift tests that quantified the uplift resistance of roofing tiles with various attachment methods.

The resulting method was incorporated into the Standard Building Code (SBC), and later the Florida Building Code (FBC), and the International Building Code (IBC) as well.

Some concrete roof tile applications have been tested to perform in sustained wind speeds of up to 180 miles per hour when installed to industry and manufacturer guidelines.

While certainly beautiful, concrete tile roofs are also quite functional in the face of subtropical climates and high-wind regions. While no roof is completely windproof, tile roofs perform very well compared to many other roofing materials. Concrete tiles are notably sturdy and long-lasting, and can manage sustained winds as well as greater wind gusts. Although tiles are heavier than many roofing materials, their greatest advantage in wind resistance derives from their shape and construction, which allows free wind travel through the system, greatly reducing uplift stresses on the roofing assembly.