By Rob Haddock, Director Metal Roof Advisory Group

With the frequency of extreme weather conditions on the rise — from 10+ feet of snow in sunny California to tornadoes ripping through the Midwest and hurricane events in coastal communities — builders are realizing the need to focus more on reinforcing their construction projects against the potential damage severe weather conditions can inflict on homes and businesses.

A roof is the first line of defense against the fury that nature can exhibit when the weather turns awry.

So, what do builders need to be aware of? What are the areas of concern and what can be done to combat extreme weather conditions. Let’s dig in.

Damaging Winds

Wind causes “uplift” (suction) forces on a roof. Certain areas of the roof experience higher uplift forces than others. A metal roof can be tailored to withstand virtually any uplift force desired or mandated by building code authorities up to and including Category-5 hurricane forces and even tornadic wind forces.

This degree of wind resistance is not something that magically happens but is the result of careful design, engineering, testing, attachment and installation details. Unlike many other roofing materials, metal’s mechanical properties don’t change with age, so it will perform as designed for its decades-long service life.

Of course, the more durable the design, the more expensive the roof. So, it may not be economically prudent to request design beyond code requirements — but that is a personal/business decision and certainly an option. Engineering standards affecting wind forces have also increased in recent decades, so a roof designed in 1990 may not be compliant with today’s standards. Roof durability in a windstorm may also depend upon the building’s structural design. (The roof won’t survive if the structure to which it is attached collapses.)

According to Monroe County Florida’s staff summary post-Hurricane Irma inspections found that “metal roofs fared far better than those roofs covered by asphalt shingles,” and in recent years, county officials even proposed an ordinance to require all new or replacement roofs to be metal. That’s a true testament to the sustainability and durability of metal roofing, particularly in high-wind-prone areas.

The exceptional performance of metal roofing in high-wind conditions is due in part to its structural attachment methods, frequency and interlocking features, reducing the ability of wind to detach the panels. The most important factor is that metal (unlike membranes or asphaltic materials) is an inert material, so its mechanical properties do not diminish with age and exposure to ultraviolet and other environmental conditions. In other words, it will behave as tested throughout its life of 60 years or more.

Standing seam metal roofing has a distinct advantage over other roof types, such as membrane and hot-applied asphaltic roofs because it serves as a “structural” covering, so it can be engineered to withstand almost any force imposed by wind. When so designed, some structural standing seam profiles can withstand extremely high wind pressure, making metal the roof of choice in high-wind regions.

By increasing the frequency of attachment, increasing the gauge thickness of the metal, decreasing the panel width or using external seam clamps like the S-5! WindClamp — or any combination of these together can measurably increase the durability of the roof in a windstorm.

Hail

Building materials absorb hail impact differently. For example, hail may cause small dings in siding, gutters or asphalt shingles, but if it is large and dense enough — the possibility of a roof puncture becomes greater.

Metal roof material is the best defense against hail. Potential damage depends upon the size and hardness of the hailstones, the type and gauge thickness of metal and the substrate to which it is installed. Steel roofs do not dent from hail as easily as a vehicle, which uses softer grades of steel that can be easily molded into the sleek lines and curves of an automobile.

Generally speaking, up to one-inch hail will barely leave a visible trace on a 24-gauge steel roof. Copper (16 oz.) is another story because it is a softer material. Contrary to the claims of many “storm-chaser” contractors, it is extremely rare that hailstones, even of significant size and velocity, hinder the roof’s function, or mandate its replacement. Claims to the contrary are almost always ill-founded. A recent research project by the Metal Building Manufacturers Association provides such evidence

Snow or Freezing Rain

Snow and freezing rain pose unique challenges for any roof type. Snowpack (the buildup of snow and ice on any roof) can produce significant sliding forces and result in its sudden release, dumping tons of the fallout below the eaves in a matter of seconds. This causes hundreds of millions of dollars in property damage, personal injury and even death each year.

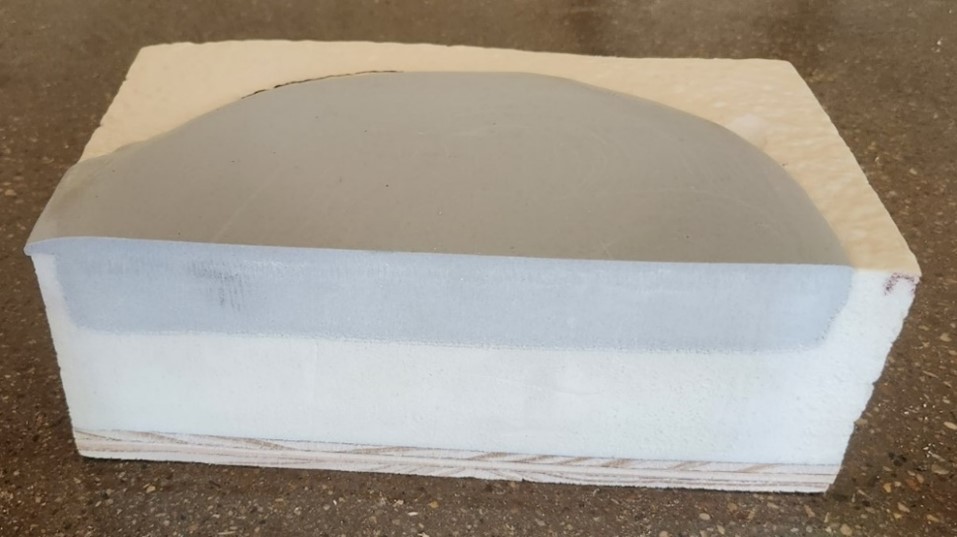

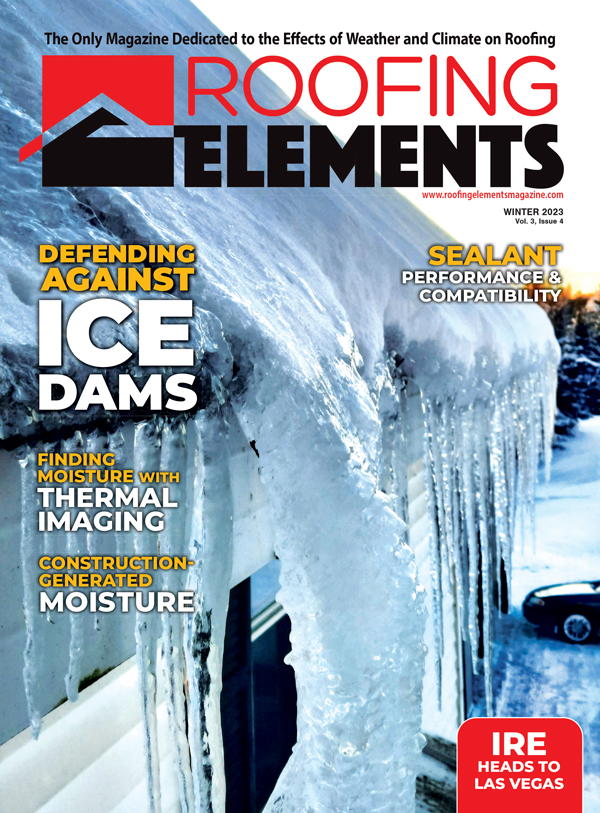

Re-freezing meltwater on a roof can have extremely damaging effects. The incredible force of freezing water is known to break solid steel engine blocks — and can certainly wreak havoc on a roof. When the roof warms from building heat loss, snowpack begins to melt — the meltwater runs down the roof and often refreezes on the eaves. The eaves are as cold as the ambient air temperature. So, when ambient temperature is frigid, ridges of ice (ice dams) can build up leaving ensuing meltwater no means of drainage at the roof edge. Static water pressure above the ice dam may infiltrate the roof panels, potentially causing damage to the exterior walls, insulation attic and building interior, resulting in watermarks, rot and mold. Left unattended, this problem will perpetuate each time the same conditions exist. Ice dams as thick as 18” or more have been reported

Pitched metal roofs manufactured from material that results in a slippery surface can pose sliding snow, sudden rooftop avalanches and ice hazards in the discharge areas below the eaves. The best way to mitigate snow and ice on a metal roof and reduce liability caused by the avalanche is by installing a scientifically tested and engineered snow retention system specific to the snow loads expected on your particular roof, like the variety of snow guards offered by S-5!

Lightning & Fire

If lightning and fire are a concern, metal is the preferred roofing material since it will not spark and ignite into flames during a wildfire or lightning strike. Because metal is non-flammable, the odds of external fire spreading to the building are also reduced.

To suppose that a metal roof “attracts” lightning seems intuitive but is a complete misconception. Lightning finds its way to earth based primarily on building height as compared to its surrounding terrain, structures or trees, so a metal-roofed home is no more likely to be struck than any other roof.

Most damage (and fires) resulting from lightning strikes are caused by the lightning charge passing through non-conductive materials like wood, masonry or stone on its way to the ground. So, a steel-framed, metal-roofed building is the safest place to be during a lightning storm because any potential strike has an easy, conductive path to the ground. Just keep some distance from that path (stay away from the walls).

Combating Extreme Weather Conditions with Metal Roofing

Metal is considered the most environmentally friendly and sustainable roofing material available, known for its long-lasting performance and reliability. Metal roofs are 100% recyclable and are made with a minimum of 25% recycled material, depending on the type of metal. Metal is also the most durable in instances of extreme weather conditions.

A metal roof can be tailored to withstand virtually any wind uplift force and can be reinforced even post construction; it is resistant to hail damage; it can handle snow and ice with an engineered snow retention system; and because it is non-flammable, it will not spark and ignite into flames during a wildfire or lightning strike.

Manufacturers need to develop products that seek to increase a roof’s resilience and address some of the most challenging conditions roofing and exteriors projects may face. S-5! has created a variety of roof mounted solutions to strengthen a metal roof and help manage the challenges presented by extreme weather. l

Rob Haddock, director of the Metal Roof Advisory Group and CEO and founder of S-5!, is a former contractor, award-winning roof-forensics expert, author, lecturer and building envelope scientist who has worked in various aspects of metal roofing for five decades.