By Rob Haddock, CEO and Founder of S-5!

Building owners are faced with the increasing need to mount essential rooftop HVAC, solar equipment and ancillary mechanicals including screens to hide it, piping and conduit to fuel it, scuttles to access it, and walkways to maintain it.

With no clear industry consensus or standards for the design, manufacture, use or mechanical load-testing of rooftop attachments, ancillaries are often mounted by “hook or crook” violating a roof’s integrity. Sadly, the expected lifespan of any roof can become compromised when forced to function as a mechanical equipment platform.

While rooftop attachments complement the roof — making roofs much more user-friendly — many applications are not specifically engineered for design loads, nor can they be because of insufficient testing or a lack of quality assurances in production to enable the necessary testing and engineering. This is important to note because these attachments transfer live loads into the roof sheathing and structure.

Excessive weight can cause structural damage or even collapse, causing property damage, personal injury and even death — a life-safety issue and potential liability for contractors, designers and building owners.

No two roof types are alike. They vary in material, service-load capacity and their ability to withstand outdoor elements, so it is often difficult to know what attachments a roof can handle.

Roofing Material Considerations

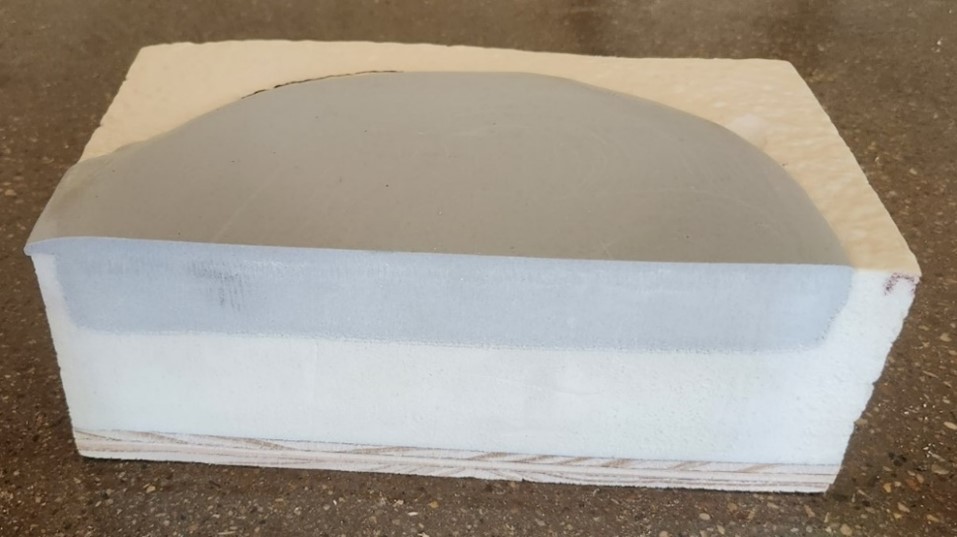

Compatibility with the roofing material plays a significant role in determining how and what can be safely attached. Materials, such as asphalt shingles, concrete, clay or composite tile, PVC, EPDM, TPO or metal, have varying levels of longevity, durability, service life and prescribed flashing details. An important objective for any roof-top attachment is that the materials, methods and details maintain sustainability for the life of the roof. This includes weatherproofing when the membrane is penetrated. Therefore, the expected service life for any roof is an important consideration.

For instance, the expected service life of metal roofing varies from 20 to 50 and even up to 200 years depending upon the metal and/or its coating type. The expected life of asphalt shingles is generally between 8 and 25 years depending upon the grade of shingle. In the hail belts of the U.S., the expected life is much shorter because shingles become more brittle with age and therefore, more prone to hail damage—indicating geography and climate at the project site also play a part in the “expected roof life.”

“Do’s and Don’ts” also vary by manufacturer within each category mentioned, so it’s imperative to understand the limitations and recommendations specific to the roofing material and its manufacturer. Manufacturers of lower-grade roofing products may not have any guidelines beyond “code compliance” or “standard practice.” Manufacturers of higher-grade warranted products generally offer guidelines on such things as sacrificial membranes, walk pads, etc. Adherence to those guidelines is often a warranty mandate. Making matters more challenging, many roof-top attachments are installed by trades outside the “roofing” industry who know little about the aforementioned issues.

Service-Load Capacity

Anything attached to a roof’s surface is exposed to service loads: upward, downward and sideways. Service loads are influenced by the weight of the ancillary, as well as the forces of nature, such as wind, snow, seismic and maintenance traffic that push and pull in different directions. Some attachments transfer service loads to the building’s primary and/or secondary structure; others to the deck or roof covering only.

To resist the in-service forces applied to any mounting system, it is necessary to know at what point the attachment fails. Only then, is it possible to calculate the required population and spacing of the attachment(s) so it cannot fail. This may require an enormous amount of testing and job-specific conditions. In many cases, engineering calculations (preferably stamped by a registered professional engineer) should be provided on a project-specific basis and should incorporate the tested ultimate strength of the attachment system with an appropriate factor of safety applied.

Outdoor Elements Affecting Rooftop Attachments

Wind: No matter where a building is located or what materials are involved, there are forces its roof and structure must withstand, including wind uplift forces. So, any attachment must also be strong enough to withstand the design uplift forces determined for the building and site. As uplift forces increase in areas with higher winds, such as hurricane-prone areas, roofs must be more durable. Roof attachments must also be designed to withstand these forces. Failure to do so can result in damage to both the roof and its attachments, posing a safety hazard to people and property below.

Metal roofing lends itself to high wind-prone areas since it can be engineered to withstand nearly any uplift force. Its exceptional performance in high-wind conditions is due in part to its attachment methods and interlocking installation where roof panels are attached to the structure of the building, reducing the ability of wind to disrupt the panels.

Snow & Ice: Snow and freezing rain pose unique challenges for any roof type. Snowpack (the buildup of snow and ice on a roof) can produce significant sliding forces to any roof-mounted obstacle. And sudden release of snowpack can dump tons of the fallout below the eaves in a matter of seconds. This causes hundreds of millions of dollars in property damage, personal injury and even death each year.

Re-freezing meltwater on a roof can have extremely damaging effects. The incredible force of freezing water is known to break solid steel engine blocks—and can certainly wreak havoc on a roof and rooftop equipment.

Hail: Building materials absorb hail impact differently. It may cause small dings in siding, gutters or asphalt shingles, but if it is large and dense enough, the possibility of roof membrane fracture or puncture becomes greater.

Metal roof material is the best defense against hail. Potential damage depends upon the size and hardness of the hailstones, type and gauge thickness of metal, and the substrate to which it is installed. Steel roofs do not dent from hail as easily as a vehicle, which uses softer grades of steel that can be easily molded into the sleek lines and curves of an automobile. Divots resulting from even severe hailstorms do not generally harm the functionality of metal roofs although they may be a cosmetic annoyance.

Heat & Cold/Ultraviolet (UV) Degradation: Intense heat and cold fatigue most roof types with constant thermal expansion and contraction. UV radiation causes accelerated aging of most roofing materials. Additionally, UV rays cause the color of roofing materials to fade, looking aged and unattractive. Over time, UV rays can also cause some materials to fatigue, become brittle, crack, peel and blister, potentially leading to leaks and mold, often necessitating costly repairs or even roof replacement.

A standing seam metal roof responds to temperature changes freely and without fatigue by design. Several domestic steel producers now offer material warranties for up to 60 years. Premium factory finishes of polyvinylidene fluoride (PVDF) paint films offer up to 40-year warranties for film adhesion, excessive fade and chalking.

Verify the Rooftop Attachment System

Attaching equipment or ancillaries to a roof can compromise its integrity if not properly designed, engineered and installed. Will waterproofing last the service life of the roof? Attachments that puncture the roof can lead to leaks, water damage, or weakened structural support if not waterproofed correctly. Proper installation methods and the use of appropriate waterproofing materials are essential to achieve total roof integrity.

Manufacturer transparency is at the heart of vetting a rooftop attachment system and any related waterproofing. When considering rooftop attachments, make sure to scrutinize manufacturer qualifications and certifications to ensure a safe, time-proven, engineered application and long-term service on every project. This transparency should extend from raw material sourcing through manufacture and product handoff.

Even if the product is installed according to the manufacturer’s guidelines, it may fail if it lacks proper testing/engineering documentation. A product cannot perform better than its design. Has the manufacturer demonstrated sufficient experience? How long the company has been in business is irrelevant. The question is, “How long has its system been in use?” Can the manufacturer substantiate its track record and prove service/durability with interactive load testing tables and real-time engineering calculations? Ask for proof of it! And verify that the manufacturer offers a meaningful performance (not just material) warranty. And always read the fine print of the warranty to validate all sales claims!

Main Take-Away

Improperly mounting roof-top attachments can result in dire consequences. It’s imperative to prioritize safety, follow recommended guidelines, and seek professional assistance as needed. Ensure regular inspections to safeguard against damage or wear caused by the attachments. Check local building codes and regulations to ensure compliance with any restrictions on roof attachments. If in doubt, seek expert resources, including a professional building envelope consultant. Know your roof and verify the durability of the mounting and attachment system. l

Rob Haddock, director of the Metal Roof Advisory Group and CEO and founder of S-5!, is a former contractor, award-winning roof forensics expert, author, lecturer and building envelope scientist who has worked in various aspects of metal roofing for five decades.