Industry experts share their tips and tricks for application temperatures, curing time, and more

Inclement weather (both moisture and temperature related) is always a concern and must be considered.

- Regarding moisture and humidity during application: Rainy weather can affect the contractor’s ability to apply the coatings to the specified dry substrates and can also affect the ability of the coatings to adequately cure. With high humidity, the air is saturated with moisture, thereby slowing down the ability of coatings to shed their evaporative components (which could be either water- or solvent-based). Low humidity, or extremely dry air, could also affect the curability of moisture-cure products such as a one-component urethane roof coating. These moisture-cure coatings rely on available moisture in the air to properly cure, with the exception being wet patch roof repair materials. These are intended to be emergency repair materials and can be applied in wet, rainy conditions.

- Regarding temperatures and wind during application: Incorrect temperatures and wind-related issues affect the ability of the coatings to be applied and properly cure. Low temperatures typically extend the drying times required for coatings to cure, which can create the need for extended dry weather in those conditions. High temperatures affect the ability to properly apply coatings, which may dry too quickly. This could affect the contractor’s ability to evenly apply the coatings, creating the need to schedule the work in cooler periods. High temperatures can also cause many coatings to surface skin over before their evaporative components can properly come to the surface and evaporate. This can cause entrapment of a portion of the coating in an uncured state beneath the cured surface film. In addition, the lack of air movement (wind) can slow drying times of coatings. High winds can also create poor curing conditions similar to high heat conditions.

Our top tips for roofing contractors may seem basic, but they are important to remember:

- Study the weather carefully and plan each and every project around the weather. If you are forced to complete spot repairs in inclement weather, select a product suitable for that purpose or temporarily protect the repaired area while the coating materials are being applied and during cure. Scheduling roofing work during “roofing season” for your specific area and climate will pay off in the performance and longevity of your roof coating system.

- Always incorporate each roof coating material manufacturer’s application recommendations into your planned work. Coating manufacturers want your project to succeed and are typically clear on the weather parameters and drying times needed to apply their specific coatings. Each coating is different in its drying performance characteristics, so there is no substitute for reading the manufacturer’s recommendations and passing them on to your work crews.

Our tips for coatings are simple, but incredibly important:

- Always perform a thorough roof inspection to determine the best combination of materials for the necessary repairs. While most repairs can be handled with a brush-grade mastic, larger gaps may first need a polyester reinforcement.

- When applying synthetic rubber coatings, the roof must be free from grease, dirt, moisture, and all foreign products (using a power washer works best). For small repair jobs, one could use a brush and water (repeating if necessary) until the targeted repair area is properly clean. Remember to let the roof dry before applying the coating, and refer to the manufacturer’s instructions for the proper temperature range.

• Product storage: Whenever possible, have the coatings or adhesives delivered to the job site as close to the project start date as possible to avoid prolonged exposure to the elements. Always follow the proper product storage guidelines and keep products stored in as close to room temperature (70°F) as possible, in the original packaging, and in a dry location. This is best handled using a heated warehouse or a weatherproof hot box. Do not store the materials in concentrated loads on the roof to avoid overloading the structure.

• Product heating: With proper storage, heating should not be necessary. However, for some products, heating may be needed immediately before application to assure the proper viscosity is obtained for adhesives. This can be accomplished through the use of heated storage cabinets or through warming devices that use circulated oil. Carefully review the product guidelines to ensure proper heating takes place without risking product damage.

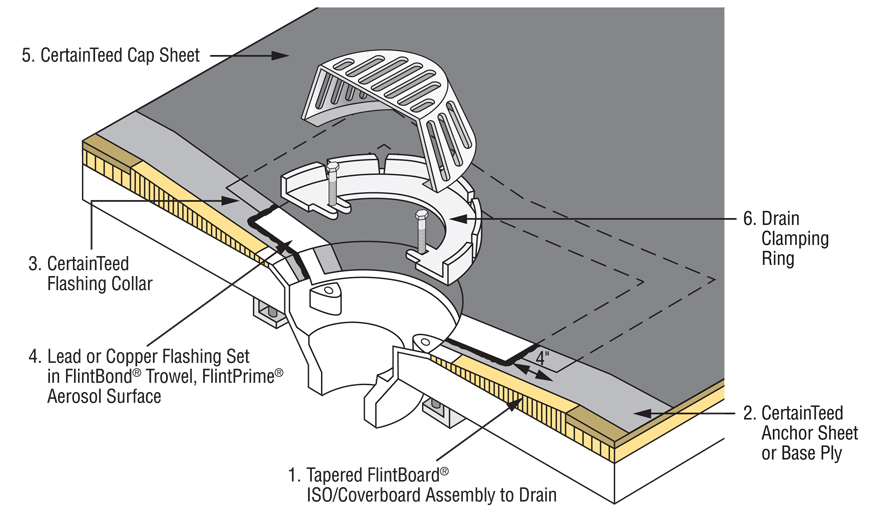

• Surface preparation: Never apply a product to a frost-, snow-, or ice-covered roof surface. Most adhesives require a dry substrate. Keep an eye on the dew point temperature, as dew will form on the roof surface during cold mornings. Roof surfaces must be at least 6°F above the dew point and rising before applying the product. It is critical that the substrate is dry prior to product application. A good, simple tip that some contractors use to check if the roof substrate is completely dry is to roll white filter paper on the surface to observe if any moisture is present. If the paper darkens, the surface is wet and must dry out further prior to application of the adhesive/sealant.

• Substrate surface temperature: Even though ambient temperatures may be warm enough, the substrate temperature must also be in the proper temperature range. Darker substrates will absorb more heat and will warm and dry the substrate. Use darker, primed coverboards and smooth, slag surface membranes to aid in the natural warming of the substrate by the sun.

• Cure time considerations: Colder temperatures will slow the cure time of most cold-applied adhesives. An adhesive that may normally cure overnight at 70°F may take several days to cure at 40°F. Watch the weather forecast to make sure precipitation is not coming while the product is curing. If a sealant has not formed a surface skin before moisture intrusion, it can negatively impact the curing and subsequently the desired properties of the product. In short, account for longer cure times in cooler temperatures.

• One of the biggest advantages to tripolymer sealants is that they usually require no surface preparation, even when the surfaces are wet, frozen, dirty, oily, or even greasy. For best results, the surface should be basically clean and surface-dry, although dampness from dew will not interfere with this type of sealant’s adhesion. Tripolymers are also extremely flexible and retain their flexibility over extended periods of time. They resist weather well and are virtually impervious to UV light.

• Hybrid sealants are a perfect choice for most membrane roofing applications. Hybrid sealants will cure in damp conditions and can be used as a “night seal” when the job lasts too far into the night.

• One great tip is, when you need to tool a bead of solvent-based sealant, a drop or two of liquid dish soap can be used as a barrier on your finger or tool so that the sealant does not stick to you or the tool.

• Also, when applying brushable-grade triploymer sealants or coatings, apply them in thin coats so that the product does not run. Two coats are generally recommended to ensure complete coverage.

Two primary considerations for applying adhesives and sealants are:

- The substrate must be clean and dry.

- The product must be stored and applied at temperatures within the working limitations of the product.

Two helpful tips to remember:

- A general rule of thumb is adhesives and sealants should not be exposed to inclement weather for a period of 24 hours following application.

- Liquid solvent-based adhesive materials typically have a wider range of application temperatures, but may be affected by ambient conditions (i.e. solvent-based adhesives tend to wick moisture from the air in high-humidity environments and will develop a moisture film on the adhesive surface in cooler temperatures).

Our most important recommendations revolve around product compatibility:

- The contractor must take into consideration when using adhesives or sealants with any self-adhered roofing underlayment or flashing tape that it must be compatible with the mastic used on the membrane (SBS, acrylic, hot melt, or butyl).

- Using an adhesive or sealant that is not compatible will cause a negative reaction with the self-adhering product and cause the mastic to run out or bleed, making the membrane not fully waterproofed. And it can cause quite a mess!

• When caulking at temperatures below the dew and frost point (40°F and lower), the surfaces must be clean, dry, and frost-free. A torch is not recommended to dry the joints, as this may leave hydrocarbon deposits on the surface that can impede adhesion. Also do not dry the joints with a heater or blow dryer; heating can cause moisture condensation on the metal once it cools. Metal surfaces can be dry wiped then cleaned with a solvent.

• No sealant should be installed immediately following or in anticipation of rain or snowfall. If unexpected snow or rain occurs, note it in the project log so field testing can be done on the potentially affected areas approximately two weeks later.

• When sealing roofing or gutters, proper gunning technique is critical for long-lasting watertight seals. Begin your bead at least ¼” before the seam or crack. Press down firmly and make sure to maintain solid contact with the surface to ensure the sealant will be forced into the seam and adhere securely. Press down hard enough that you feel the resistance of the surface pushing back. When sealing a lap joint, the coating should be ample enough to act as a gasket, yet thin enough so there is no dam to impede an easy flow of water toward the downspout.

• Surface preparation is important; the surface should be clean and dry. Remove any loose material or scale that would prevent good bonding, and remove any oils with alcohol or another solvent.

• It is important to verify the recommended temperature and humidity range in which a sealant can be applied. There are many different sealants on the market. From gunnable, advanced polymer sealants to butyl tape sealants, they all have different recommendations for application. Many sealants require the substrate to be clean and dry at the time of application. Follow all of the manufacturer’s surface preparation recommendations.

• It is also important to distinguish between a sealant’s service temperature and its installation temperature. For example, a sealant may have a service temperature from -75°F to 300°F once it is cured, but only have an installation temperature range of -35°F to 140°F.

• Try to store your sealant in a climate-controlled area until its use. The sealant temperature will change much slower than the air temperature. The interior of a vehicle or even an insulated cooler may help keep your sealant from being much hotter or much colder than the ambient air temperature when it comes time to apply it.

• Follow the manufacturer’s recommendation for bead size. A bead that is too small may negatively affect the sealant’s weatherability once it is cured, and a bead that is too large may lengthen the sealant’s cure time or even prevent it from completely curing on the inside. More is not always better when it comes to sealant.