By Philip Jacklin, Diversified Fall Protection

Rooftop work can be dangerous enough in perfect weather conditions, but adding wind, rain, snow, fog, hail, or other inclement weather can bring challenging complications that increase a roofer’s overall risk factor. Additional precautions must be taken to ensure that roofer safety is never compromised, and the task can still be completed. When working at heights, fall protection must always be the top priority.

Strong winds, slippery surfaces, and reduced visibility are some of the factors inclement weather brings that can increase the likelihood of accidents, resulting in injuries or even fatalities. Unfortunately, OSHA does not provide specific regulations or standards for employers to help keep their workers safe during inclement weather. However, OSHA’s General Duty Clause requires employers to provide a workplace that is “free from recognized hazards that are causing or are likely to cause death or serious physical harm to [their] employees.” Furthermore, OSHA outlines specific duties for building owners when it comes to their rooftop (AKA walking working surface).

As with almost any other workplace hazard or dangerous environment, inclement weather is something that can be anticipated, and proactive measures can be taken to prevent incidents and protect workers from harm. Depending on the type of expected inclement weather, different measures can be taken to increase individual workers’ safety:

Strong Wind

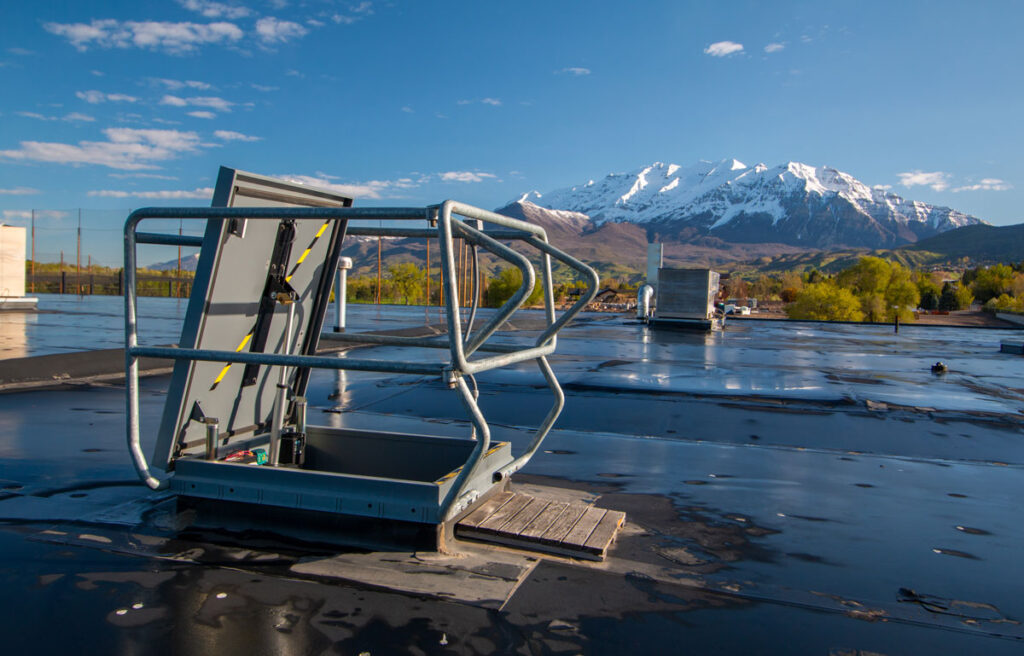

If a crew is working under strong wind conditions, be mindful that certain objects can increase a roofer’s risk of falling. If a roofer is carrying around large sheets of plywood or metal, that object can act like a sail and potentially cause them to lose stability. Unattended and unsecured objects may also get caught by the wind, becoming dangerous for workers at height, or equipment and people on lower levels. It is important to always keep as much distance between the work zone and the edge of the walking working surface as possible. If the roof is ladder-accessed with hatch doors, consider that strong winds can make hatch doors more difficult to operate. An upgrade to an automatic open/close system before an anticipated storm could be a proactive measure with significant value to future worker productivity and company safety initiatives.

Rainy weather

Rainy weather creates slippery conditions, and slippery conditions are more likely to cause a roofer to slip, trip, or fall. If possible, map out the job site and lay down weatherproof mats along work areas to give more traction on rooftops. A slip on a flat slope roof could cause sprains or other injuries, but a slip on a sloped surface could bring more serious accidents, including the potential to fall off the roof.

If work is expected to occur during extremely wet conditions, it might be necessary to temporarily use a vinyl-coated or an alternative harness made of water-resistant materials. Excessive water has the potential to cause irreparable damage to a body harness and might make it unusable for future use. Every time a work environment changes, it is important to evaluate whether the current PPE being used is appropriate.

Freezing temperatures

Freezing temperatures can cause ice to develop on a rooftop, further increasing the chances of a slip, trip, or fall occurring. Additionally, freezing temperatures and snowfall can prevent certain anchors from functioning properly. For example, a swivel anchor might not be able to move as freely as it would under normal, warmer weather conditions. Upon inspecting anchor points before each use, if an anchor point is found to not be working properly, it is not safe to use that anchorage until better weather conditions arise. Consult with your job site/organization’s Competent Person to discuss alternative anchorage solutions.

When the temperature plummets, it is likely roofers will need to wear additional layers of clothing for warmth. Before starting work and during the pre-use harness inspection, be sure to verify that the roofer’s body harness still fits properly over the additional clothing. The body harness must be the outermost layer worn, so as not to obstruct access to the dorsal D-ring. It is likely some roofers will need to upgrade to a larger-sized harness in anticipation of winter work to accommodate bulky clothing and still provide an optimal fit that will keep the roofer safe in the case of a fall. If a harness is not donned properly per manufacturer specifications, it cannot be guaranteed that it will work exactly as designed during a fall incident.

Specialized PPE can provide a safer work environment for crews. For example, certain products can attach to the bottom of work boots to provide extra traction on icy or slippery walking working surfaces. All PPE must be worn during body harness pre-use inspections, to confirm they do not interfere with the user’s Personal Fall Arrest System (PFAS).

Effective Planning

Adjusting your pre-task planning process to accommodate inclement weather will better prepare your crew, despite whatever weather conditions arise. As the saying goes, “fall protection starts on the ground,” because your fall protection program is only as good as your planning process. Be it rain or shine, training and well-prepared rescue plans are vital to the success of your fall protection program. It is important to ensure emergency response plans are understood and communicated by your crew, and that each component of your fall protection equipment is inspected before each use, as required by OSHA.

Finding the right solution

Eliminating the fall hazard altogether is the preferred method of fall protection. If the fall hazards cannot be eliminated, then the next best solution is a passive form of fall protection, such as guardrail. Most passive fall protections would require no modifications for use in inclement weather.

If a passive fall protection system cannot be used, an active system will still protect users during inclement weather, however, it will require user interaction and training to protect properly. Active solutions include travel restraint systems, which prevent users from reaching a hazard, and fall arrest systems, which stop a fall once it has occurred. While all these options can save roofers’ lives, there is still more risk than eliminating the hazard or using a passive system. λ

Philip Jacklin is Continuing Education Program Manager for Diversified Fall Protection. Since 2018, Philip has been training workers on best practices when using their fall protection, and advising safety managers, EHS leaders, plant maintenance managers, and other safety professionals on how to create more efficient fall protection programs.