Worker safety, material handling,

and best weather conditions

BY JESSICA FRANCHUK

How would you describe the ideal roofing day? Chances are you’re like most roofing contractors who prefer “the trifecta”: warm, dry, and calm. Depending on where your business is based, you might be lucky to experience those perfect days more often than not. But for those of us in Northern and Midwestern climates, winter brings brutal cold, piles of snow, and howling winds. Unfortunately, you can’t just take off three months out of the year if you want to get ahead in today’s competitive roofing market. It’s important to keep your schedule full (and your workers employed) all 12 months out of the year. And, with the proper considerations of weather, planning, material storage, and safety, that is possible.

The Dan Perkins Construction crew pushes through the Upper Michigan chill to install a metal roof while there is daylight left.

Weather or Not

While the trifecta of warm, dry, and calm is not often the norm between fall and spring, if you hit two of the three, you can still have a solid, productive day on the job site. Todd Meinhold, President and Owner of HD Quality Builders and Ridgeline Safety Systems, shared, “We do snowy installs every year. [Before we start each morning], we have tool box talks on things to remember for that day, depending on the conditions.” It’s important to have a plan and communicate with your team before anyone gets up on the roof. Remember, you might have looked at the weather forecast, but until you are on the job site and see the actual conditions you have to work with, don’t hold yourself and your team to that day’s plan.

You and your crew need to be flexible and prepared to change gears as the weather and sun shift. Meinhold added, “Plan your work on cold days to be on the South or West sides of the roof, as the frost melts off of them first. Then, switch to the North side when you can—it is a bunch of jumping around, but keeps the job moving forward. If all sides are done but the North and the weather doesn’t improve for a few days, then there is no work. Always plan your days around the sun!” Weather can be unpredictable, so adapt as needed. Your crew should expect scheduling changes due to inclement weather and, if the weather improves, they should be ready to proceed to the site on short notice.

Winter brings shorter days as well and, with less sunlight, plan on being on the roof fewer hours than on long summer days. This may lead to a job taking more days, but the crew’s safety is critical. Dan Perkins, Owner of Dan Perkins Construction, said after a recent metal roofing job in Michigan’s Upper Peninsula: “I asked the crew to share something about working in the cold. They said, ‘it’s like trying to ride a bike with training wheels—everything is harder and clumsy and slow going.’ But when the weather warms up, they will be tougher and ready for the higher production that is only possible in warm weather.”

Craig Swanberg, a member of the Dan Perkins Construction crew, is appropriately dressed to handle the wind and cold.

A light dusting of snow can be quickly removed with a broom or leaf blower. Even small amounts of snow can hide dangerous ice patches, so clearing the roof is critical. Photo courtesy of HD Quality Builders.

Safety on the Job Site

Contractors don’t get paid until the job is done, and not at all if they can only install half of a new roof. If a big snowstorm is headed your way, prep the site with tarp-covered sections before the snow falls so you have less area to clear following the storm. Take the time before a storm to tack walk boards in place on the roof as well to make future cleanup easier.

Meinhold also recommended setting multiple anchor points on a roof prior to snowfall. “Install [anchor points] in places that get you not only up on the roof, but around on the roof. If a worker has to unhook to get to another anchor, the chances of slipping or falling increases exponentially. Leave safety ropes on the roof tied off (and in multiple locations) so you can attach at the eave before entering the roof. Emphasize to the crews that slow and steady keeps everyone safe,” he advised.

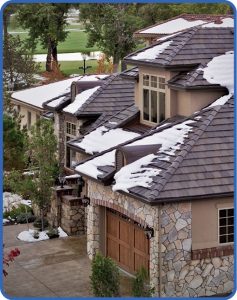

Winter weather can occur even when least expected. Plan ahead and review local weather forecasts. Photo courtesy of Boral Roofing.

If the weatherman calls for snow and you planned to work the following day, that doesn’t mean the job is halted until everything melts. Removing snow from the decking can be relatively simple. A shovel and broom for heavy, wet snow, or a leaf blower for light, fluffy snow, make quick work of the job. For concrete roof decks, the Canadian Roofing Contractors Association (CRCA) recommends, once the surface is dry, immediately priming the deck surface and coating it with a light coat of bitumen. This will make it less difficult to remove any further ice or snow, and makes it very easy to dry out the surface.

You might be tempted to wear crampons or similar traction devices on an ice-covered roof, at least until you’ve cleared it. However, these can seriously damage roofing materials and are not recommended for roofing use. There are also specialty boots manufactured specifically for roofers, but these are also not intended to be used in winter weather or on ice- or snow-covered roof surfaces. Stick with a slip-resistant rubber-soled boot with insulation rated for the necessary temperatures. And of course, utilize all appropriate roof anchors and tie-off points. Black ice is a real threat that can make a surface look clean when it is in fact covered by a dangerous thin coating of ice.

Also be aware of high winds or wind gusts, especially if installing a metal roof with long panels. High speed winds don’t just make it feel colder—you’re essentially standing on the roof with a giant metal sail in your hands. This not only increases the chance of being blown around (and off!) the roof, you also run the risk of a nasty cut from the its metal edges.

Material Matters

Deliveries that will be made in cold weather need to be carefully planned out. It might not be possible (or convenient) to schedule them ahead of time, but look at the coming weather and adjust as necessary for any heavy snowfalls or subzero temperatures headed your way. Roads might become impassible, or large trucks might struggle to perform in freezing temps. If you have the materials on-site ahead of time, be sure they are appropriately protected and covered per the manufacturer’s suggestions. Meinhold added, “Look ahead at the weather days in advance so your materials can be staged in places that don’t affect possible snowplowing (or trees/limbs falling on them).”

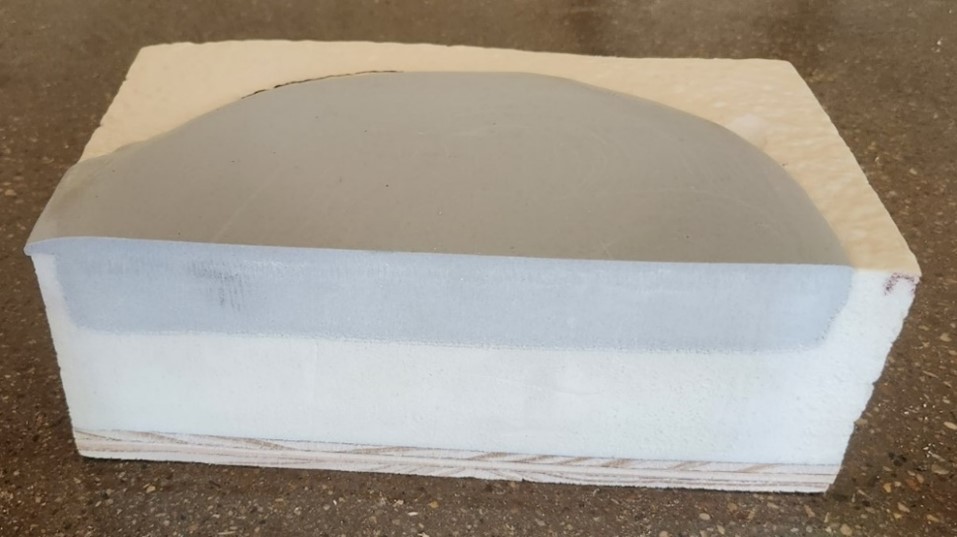

Appropriate storage and handling of adhesives and sealants is especially important during cold-weather installs. MFM Building Products, a manufacturer of weather barrier products, recommends installing its underlayments in fair weather at temperatures of 50°F or above. Their literature states, “Warmer temperatures enhance the adhesion properties of the rubberized asphalt membrane; reducing the chance of problems during the installation process.” However, since cold-weather installs are not happening in 50°F weather, following their recommendations for cold weather underlayment application is advised: Make sure there is no moisture present on the substrate, which will prevent the product from fully adhering. The underlayment should be kept in a heated area until use. When warm, the membrane is more flexible and has better adhesion than when cool. The product should be kept inside a heated building, vehicle, or inside a hot box with a temperature of at least 60°F. A heat gun or hair dryer may be used to gently warm the membrane and the substrate. If the product does not appear to stick readily, use a spray adhesive to ensure positive adhesion.

Regarding sealant application and curing during cold weather, Novagard, maker of custom engineered silicone sealants, adhesives, and coatings, advised, “When caulking at temperatures below the dew and frost point (40°F and lower), the surfaces must be clean, dry, and frost-free. A torch is not recommended to dry the joints, as this may leave hydrocarbon deposits on the surface that can impede adhesion. Do not dry the joints with a heater or blow dryer. Heating can cause a problem with moisture condensation occurring on metal once it cools. Metal surfaces can be dry wiped, then solvent cleaned using the two-rag wipe method. No sealant should be installed immediately following or in anticipation of rain or snowfall. If unexpected snow or rain occurs, note it in the project log so field testing can be done on the potentially affected areas approximately two weeks later. In cold temperatures, the cure rate may be slower because colder temperatures generally have lower humidity levels that will affect the cure rate.”

Many other roofing materials can become difficult to work with after just a 10°F temperature shift. Asphalt shingles can lose their flexibility and become harder to cut. Their self-sealant strip may not activate in the cold (especially on a cloudy, cold day), making them prone to future blow off. If the weather is too cold and there is no sun around to add that bit of necessary warmth, the shingles need to be hand-sealed with a small amount of roofing cement beneath each individual shingle. This will keep them safely in place throughout any high winds and, once the weather heats up, the self-sealant strip will activate.

Most material manufacturers can advise on the best storage and handling of their specific product in cold weather, including if the product (or the surface) can or cannot be heated, as noted in the earlier underlayment and sealant examples.

Dressing in the right layers for the day’s conditions can be the difference between a good roofing day and a bad one. Photo courtesy of Carhartt.

Worker Warmth

When the temperatures drop, the risks for cold stress injuries increase. Cold temperatures and windchill cause heat to leave the body more quickly, putting workers in danger of cold stress injuries (see sidebar at left). Dressing in layers can help ward off the chill and prevent damage like frostbite and hypothermia, but it is important to choose the right layers.

Amy Hellebuyck, Communications Manager for Carhartt, suggested, “When I think of roofers and the gear that would be helpful, a few ideas come to mind: an outer garment that allows greater movement, or clothing with wind-fighting technology. Also, our consumers love to layer as the temps change throughout the day, which makes a vest or sweatshirt a great choice [below the outer layer].” Lightweight, insulated clothing will fit well beneath a heavier winter coat without creating movement-hindering bulk.

Several clothing brands also make high-tech layering pieces originally created for cold weather athletics, making them ideal for those doing outdoor physical labor. These pieces wick away sweat while keeping your core body temperature up (much better than the long johns of old). For an additional bit of warmth, you can find battery-powered heated jackets and vests. Makita USA has one option that includes three heat settings for five heat zones, all powered by their standard 18V battery.

No matter how warm you might feel while moving about on a cold roof, Meinhold reminded, “Take frequent breaks. Cold hands and feet make for distracted employees, and that’s when accidents happen.”

Tools of the Trade

Frozen equipment quickly becomes a massive time-waster on a job where time is of the essence. Air compressors are a common culprit for cold-weather issues, but some pre-planning can keep them (and your crew) running. A tarp and a work light might do the trick, warming the compressor and hose to keep them from freezing. On a sunny and chilly (but not brutally cold) day, setting the compressor in the sun is arguably the easiest method.

If you know that your air lines tend to freeze since they can’t be kept under a heated tarp all day, have a spare set or two in a warm place (the customer’s garage or basement should work) and swap them out as needed. Malco Tools also shared, “Make sure you have a water filter on your air line. Typically, compressed air accumulates moisture, and it could freeze in the air motor. Most of the time it doesn’t cause any harm, but you would have to warm up or thaw out the tool. You can then put a few drops of oil in when it is running again.”

Cordless tools also cause headaches in cold weather, with batteries that seemingly die in half of the normal time. Store extras in a heated vehicle or heated tent on-site so you don’t spend precious minutes waiting for them to charge. Regarding batteries and temperature extremes, Makita USA said, “Very high and very low temperatures can be the enemy of all batteries, regardless of the brand. For the best results, seek out a battery that has been engineered to deliver consistent power and run time in extreme temperatures, some even down below 0°F.”

Final Concerns

With the proper considerations and prep, it’s possible to keep roofing throughout the entire year. Meinhold’s final words of wisdom were, “Winter work is about keeping your great employees! If you lay them off, chances are they will be looking for work elsewhere. And when good help is hard to find, spend the money to keep them all year long.” During a recent cold spell where it hit -20°F, Perkins planned an indoor training program for his crew (getting certified to install zinc roofing for a project they have lined up in the spring). He also emphasized how important it is to keep them working even when they can’t be up on the roof—they were all raring to go a couple days later when the midday high was in the 20s. So keep an eye on the weather forecast and be ready to roof!