A new astm standard for qualification of synthetic underlayments

BY GREG KEELER, TECHNICAL SERVICES LEADER, OWENS CORNING

Synthetic underlayments have been available for over 20 years, and very early versions left a bad impression on some contractors. However, things have now changed for the better.

Why Synthetic Underlayment?

Roofing contractors are always looking for ways that they can do their job more efficiently, and seeking products that they feel improve the quality and durability of the installed roof. Asphalt felt underlayments, also referred to as “felt paper” or “tar paper,” have served the roofing industry well for decades. However, there have always been shortcomings of these products.

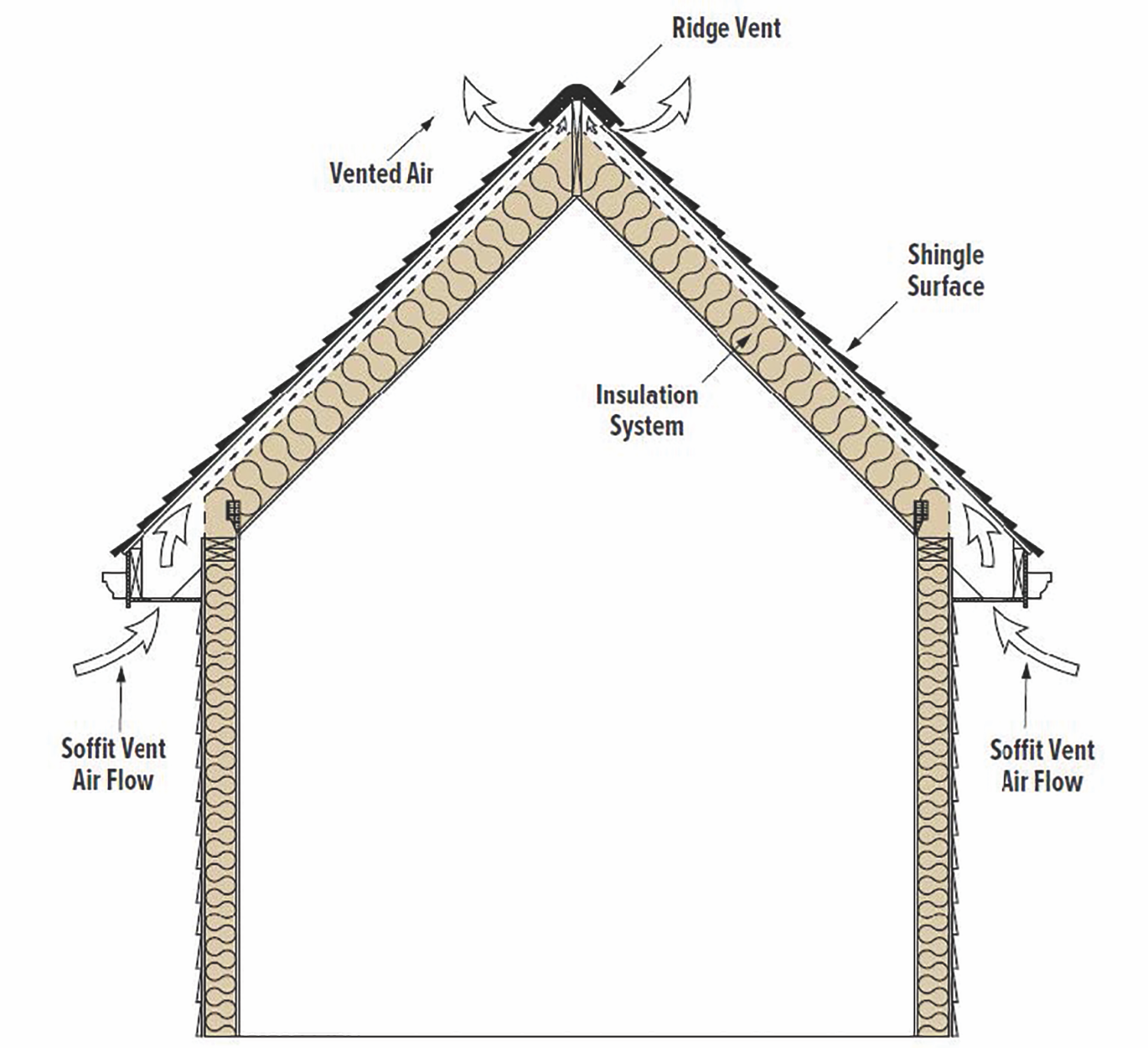

As the monikers indicate, the most prevalent drawbacks to these paper products is that they are essentially paper that has been saturated with asphalt. The organic paper core of these products tears easily and is sensitive to changes in humidity. Also, because the paper core isn’t 100% saturated, the paper can still absorb moisture, which can cause waviness when installed on the roof. Generally, the heavier the paper core, the higher the potential for waviness.

The other major drawback of these products is their propensity to tear easily. Tearing is a concern especially where it occurs around fasteners when the product is enduring foot traffic during roof covering installation. Tearing can also be a major issue when it comes to the ability of the underlayment to remain in place in a high-wind event, especially if the roof covering is blown off.

The above concerns were the primary drivers that led to the development of synthetic underlayments. Synthetic underlayments are designed to provide superior strength—including resistance against both tensile (pulling) and tearing. However, the test standards for these products never caught up to their product development—until now.

History of Synthetic Underlayment Testing

Early synthetic underlayments were tested and qualified for use under ASTM Standards that were intended to be applied to asphalt-impregnated felt underlayments. For many years, the International Codes (IBC and IRC) and the Florida Building Code have referenced ASTM D226, ASTM D4869, and ASTM D6757—all Standards that were intended to apply to asphaltic felt underlayments.

The problem with that approach was that those Standards are primarily composition driven. Since they were intended to be applied to asphaltic underlayments, there is very little testing that can be performed on synthetic underlayments. In fact, when a synthetic underlayment is tested under ASTM D226, for instance, the only tests that can be applied are the Unrolling, Breaking Strength, and Pliability tests. Those who have installed underlayment know these three tests alone demonstrate very little about a product’s suitability.

It didn’t take too long for the roofing industry to recognize the unsuitability of the existing felt Standards for assessing synthetic underlayments. As a result, several synthetic underlayment manufacturers worked with the International Code Council’s Evaluation Service (ICC-ES) to develop Acceptance Criteria for synthetic underlayments. Acceptance Criteria are similar to ASTM Standards, with a couple of distinct differences:

• They are not consensus-based standards—the test requirements and conditions of acceptance are determined by the manufacturer and ICC-ES with very limited input from industry stakeholders.

• The Acceptance Criteria cannot be referenced in the I-Codes as a Reference Standard.

Acceptance Criteria are deemed to be an alternative compliance path that applies to products for which the codes do not include prescriptive requirements. Additionally, they are limited to use exclusively for the purposes of obtaining an ICC-ES Evaluation Report. The two applicable Acceptance Criteria are:

• AC 188: Acceptance Criteria for Roof Underlayments

• AC 207: Acceptance Criteria for Polypropylene Roof Underlayments (limited to spunbond polypropylene underlayments)

Development of an ASTM Standard

After years of increasing numbers of synthetic underlayment products being introduced into the market—with no defined process for qualifying the underlayments—the roofing industry decided it was finally time to develop a consensus standard for these products.

Over an approximately 8-year period, members of an ASTM Task Group worked to develop a Standard that establishes appropriate and stringent performance requirements for synthetic underlayments. Task Group members represent contractors, roof consultants, product manufacturers, test labs, test equipment manufacturers, and more. This diverse membership lends credibility to the process and the resulting Standard.

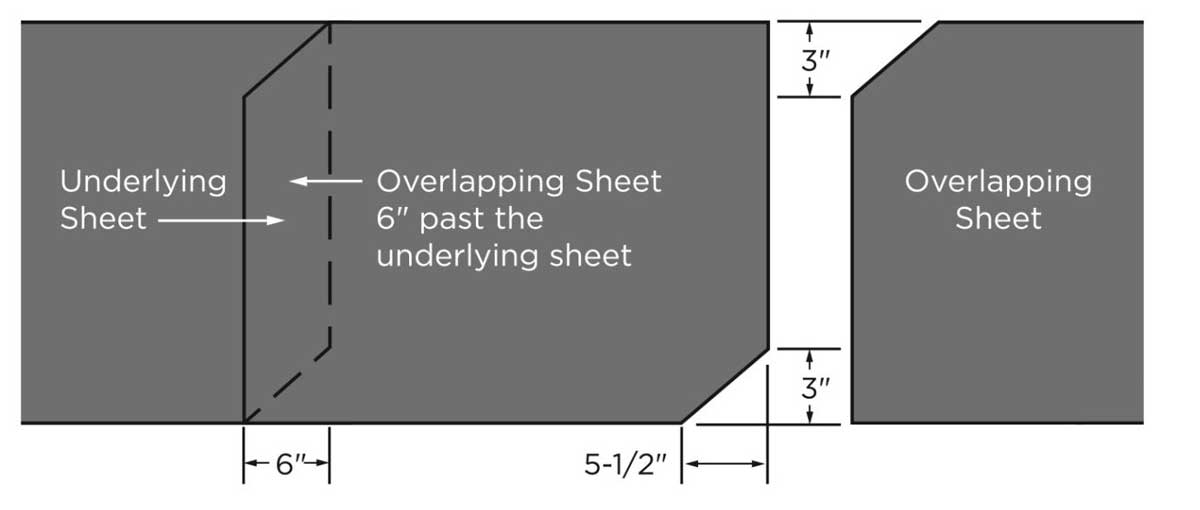

Many years of hard work resulted in ASTM D8257: Standard Specification for Mechanically Attached Polymeric Roof Underlayment Used in Steep Slope Roofing. This Standard establishes a high bar for synthetic underlayment performance and durability. It includes many test requirements that are unprecedented for underlayment standards. These tests include fastener pull-through, UV resistance, and hydrostatic resistance, among others.

The next step in this process is to propose inclusion of the new Standard into the I-Codes and the Florida Building Code. This important work is currently underway and there are many industry stakeholders working in concert to support this effort. The underlayment technology available today provides a much more diverse array of products. Product innovation continues to improve existing products and provide an even wider variety of products to complete your next job.