When designing a roof to withstand wind uplift forces, the wind speeds for that geographic region, together with many other factors that influence maximum wind forces, must be considered. No matter where a building is located or what materials it is constructed from, there are minimum standards of forces it should withstand, including wind uplift forces on its roof. So, the roof must be strong enough to withstand the maximum uplift design forces determined for the building and the building site. As the minimum uplift forces increase in areas with higher winds, such as hurricane-prone areas, roofs must be more durable. Metal roofing lends itself to high wind-prone areas since it can easily be engineered to withstand nearly any uplift force.

Design Winds Speed & Wind Forces

Wind speeds vary throughout the United States with high wind-prone areas found in coastal communities and in some mountainous regions, and lower wind-prone areas found in much of the interior states. The design wind speed is primarily determined by the area’s highest recorded three-second wind gust (measured 33’ above ground), which in turn is used to calculate the maximum overturning forces on a building and maximum uplift forces on a roof.

Wind speed (miles per hour) is translated into units of pressure (pounds per square foot — psf) for design purposes (in accordance with ASCE-7 standard for Minimum Design Loads and Associated Criteria for Buildings and Other Structures established by the American Society for Civil Engineers). One important factor affecting the calculated wind forces is the exact location within a roof. Roofs are divided into zones (for example corner, edge, interior), and the resulting forces are different in the various roof zones. Wind uplift forces are greater in the edges than in the interior and greatest in the corners.

Additionally, a building’s size and geometry impact those forces and zones. For example, a 60-foot-tall building experiences stronger wind forces than a 30-foot-tall building, even if both are located in the same area with the same design wind speed. The overall terrain and the building’s immediate surroundings also impact wind speed. Valleys, hills, slopes and cliff-sides, as well as obstacles in the wind’s path, such as nearby buildings and wooded areas, can reduce or increase wind speed and resulting forces. Wide-open terrain or open-water surfaces can set the stage for wind speed increases.

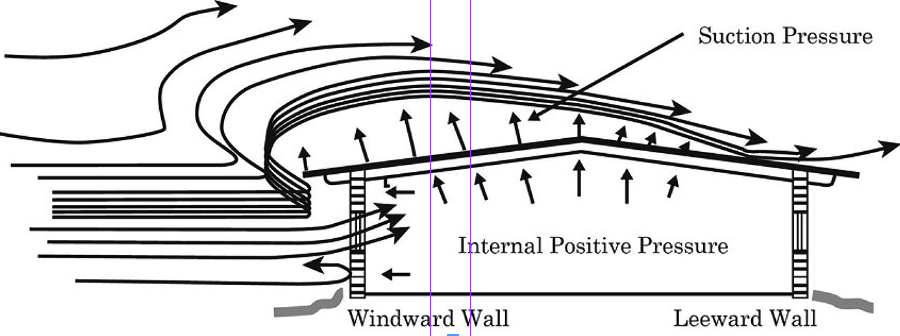

The figure shown (opposite page) illustrates how wind currents approaching a structure separate as it hits the roof’s windward edge, re-attaching at a leeward point back into the roof. The resulting suction at the windward roof area is the cause of wind uplift (vacuum) pressures. As illustrated, it is also evident that the forces are greater at the edges and corners where separation occurs.

Testing Standards for Wind Resistance

Materials, products and even site-specific project designs are tested for wind pressures to demonstrate their strength. Thus, various resistances to wind force can be attained through testing specific roof system assemblies. Some examples of common tests and standards are summarized below:

UL 580

Tests for Uplift Resistance of Roof Assemblies is one of these test standards. The uplift resistance of a roof assembly is listed as Class 15, 30, 60 or 90. The spectrums of 15-90 are comparative ratings, which are unrelated to specific wind speeds. For example, Class 90 involves 56.5 psf vacuum pressure and 48.5 psf upward pressure from below on a 10’ x 10’ specimen anchored at its perimeter.

FM-4471

Approval Standard for Class 1 Panel Roofs/Roof Assemblies lists roofs to Class (I) 60, 90, 120, 150 and 180. The nomenclatures 60-180, in the FM standard, relate to static pressure — also not wind speed. This test specimen is larger at a 12’ x 20’ minimum.

The Most Notable Meta Roofing Test Standard: ASTM E1592

Standard Test Method for Structural Performance of Sheet Metal Roof and Siding Systems by Uniform Static Air Pressure Difference. It is somewhat different than other test standards whereby sample roof assemblies are subject to increasing loads until failure. The maximum load obtained is published as an ultimate load, from which a design load is determined using the appropriate factor of safety (FS), and then used to select the appropriate products and systems.

Highest Performing Roof Type to Resist Wind Uplift

According to Monroe County Florida’s staff summary post-Hurricane Irma inspections found that “metal roofs fared far better than those roofs covered by asphalt shingles,” and in recent years, county officials even proposed an ordinance to require all new or replacement roofs to be metal. That’s a true testament to the sustainability and durability of metal roofing, particularly in high-wind-prone areas.

Metal roofing is known for its long-lasting performance and reliability. The exceptional performance of metal roofing in high-wind conditions is due in part to its attachment methods and interlocking installation where roof panels are overlapped and attached to the structure of the building, reducing the ability of wind to disrupt the panels. The most important factor is that metal (unlike membranes or asphaltic materials) is an inert material, so its mechanical properties do not diminish with age and exposure to ultraviolet and other environmental conditions. In other words, it will behave as tested throughout its life of 60 years or more.

Standing seam metal roofing has a distinct advantage over other roof types, such as membrane and hot-applied asphaltic roofs because it serves as a “structural” covering, meaning it can be engineered to withstand almost any force imposed by wind. When so designed, some structural standing seam profiles can withstand extremely high forces, making metal the roof of choice in high-wind regions.

Main Takeaways

A variety of factors affect wind uplift performance on a roof, such as geographic region, building geometries, valleys, hills and adjacent buildings. Resulting forces on a single roof also vary in different roof zones. Together, all these factors impact maximum wind forces. Understanding all the considerations is critical to ensuring proper roof design to withstand the maximum wind uplift forces the building’s roof will experience on any specific project site. l

Rob Haddock is president of the Metal Roof Advisory Group as well as CEO and founder of S-5!, the leading authority on metal roof attachment solutions. He is a former contractor, award-winning roof forensics expert, author, lecturer and building envelope scientist who has worked in the industry for five decades.